Function summary:

It is mainly used for testing and analyzing the mechanical properties of metal materials such as tensile, compression and bending. With three closed-loop control methods of stress, strain and displacement, it can calculate the maximum load, tensile strength, bending strength, compressive strength, shear strength, elastic modulus, fracture elongation, yield strength and other parameters。Test and provide data according to national standards and ISO, JIS, ASTM, DIN and other international standards。

The main machine is a floor door structure, and the middle beam is guided by a high-precision guide bar, which has high rigidity and good linear motion characteristics。

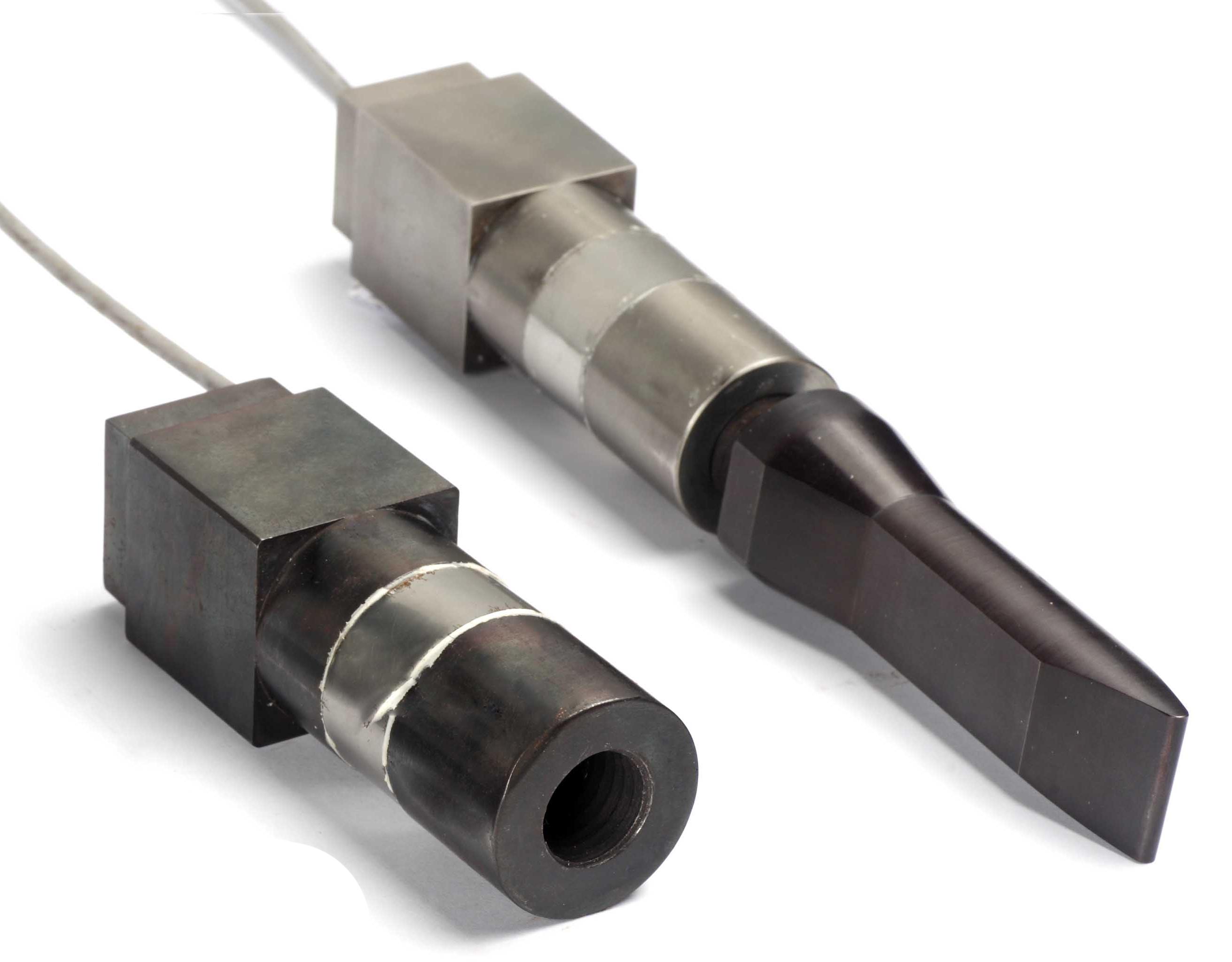

In addition to the main machine, this equipment is equipped with high temperature furnace, high temperature tensile fixture, high temperature extension meter and related fixture, which can complete high temperature tensile test under high temperature environment and maximum load 100kN。

Relevant standards:

ASTM E8/E8M-16a Test Methods for Tension Testing of Metallic Materials。

ASTM E21-17 Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials;

ISO 6892-1:2009(E) Metallic materials-Tensile testing-Part 1:Method of test at room temperature;

Metallic materials - Tensile testing - Part 2: Method of test at elevated temperature - ISO 6892-2:2011

BS EN2002-1-2006 Metallic materials test methods- Part 1: Tensile testing at ambient temperature;

BS EN2002-2-2005 Metallic materials - Test methods - Part 2: Tensile testing at elevated temperature;

BS EN10002-1:2001 Metallic materials-Tensile testing-Part 1: Method of test at ambient temperature;

BS EN10002-5:1992 Tensile testing of metallic materials- Part 5: Method of test at elevated temperature;

GB/T228.1-2010 "Metal materials tensile test Part 1: Room temperature test method";

GB/T228.2-2015 "Metal materials tensile test Part 2: High temperature test method";

HB 5195-96 "Metal High temperature tensile test Method";

GB 3562-83 "High temperature tensile test method for Metal pipes"。

Technical index

型号 | ETM105D-Z |

Maximum test force | 100kN |

Test space | Simple space |

Testing machine class | 0.5级 |

Test force measurement range | 0.4%-100%FS |

Relative error of test force indication value | ±0.5% |

Data acquisition frequency | 1200Hz |

Data control frequency | 1200Hz |

Test force resolution | 1/500000FS |

Relative error of deformation indication | ±0.5%以内 |

Deformation resolution | 1/500000FS |

Relative error of displacement indication | ±0.5%以内 |

Displacement resolution | 0.014μm |

Beam movement speed adjustment range | 0.001 ~ 500mm/min |

Relative error of beam moving speed | ±0.5%以内 |

Beam travel (without fixture) | 1350mm(equipment height 300mm) |

Test width | 600mm |

Overall dimension | 1145 (W) x 765 (D) x 2640 (H) mm |

Operating voltage | 380VAC±10%;50Hz |

功率 | 5kW |

Security protection | Force overload protection, displacement mechanical limit, voltage overload protection |

重量 | About 1300kg |